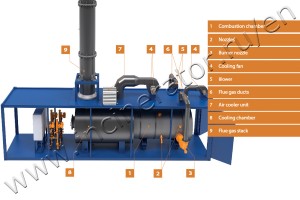

Cyclon reactor incinerators

Process description

1. Feedstock loading

1. Feedstock loading

Liquid waste:

• effluents are supplied by a pump from pre-filled containers to the nozzles of the cyclon reactor;

• the nozzles installed in the thermal protection sleeves through which cooling water circulates

Gaseous waste:

• Gas is supplied to the burners through a gas control unit

2. Waste thermal treatment

• performed in a cyclone furnace; the reactor temperature is maintained automatically by altering gas flow rate

• the air is supplied to the burner by fan; air flow is adjusted automatically, depending on the gas flow

• reactor is equipped with pilot burners, intended to ignite the main burners and to dry the lining

3. Flue gases cooling

• flue gases and the air comes from the jacket of the furnace into a cooling chamber where they are mixed with atmospheric air

4. Removal of flue gases

Option: energy recovery (steam, hot water, electricity)

Cyclon reactor incinerators:

- suitable for the disposal of liquid and gaseous waste

- applied for the disposal of hazardous waste

Advantages:

- application for the disposal of large volumes of waste

- the possibility of using heat recovery technology

- modular placement